ARMY TM 9-1240-379-34

MARINE CORPS TM 04332A-34

3-2. HEAD ASSEMBLYMAINTENANCE INSTRUCTIONS. (cont)

lNSPECTION/CLEANING/REPAIR

Inspect all parts for deterioration.

1

4 Remove old sealing compound from

recess in housing and from strips used to

Check machine screws for worn or

2

retain optical instrument window using

damaged threads.

dry cleaning solvent.

Make sure replacement optical instru-

3

5 If original optical instrument window has

ment window is free of chips, cracks,

shattered, make sure that interior of head

scratches, and discoloration.

assembly is free of glass chips and

particles.

WARNING

Dry cleaning solvent is flam-

6 Replace any damaged, broken, or missing

mable and should not be used

parts. See TM 9-1240-379-34P.

near open flame, It has a dry-

ing effect on the skin. Use

gloves, as they may prevent

cracks in the skin and, in the

case of some individuals, mild

irritation or inflammation. Use

dry cleaning solvent in well

ventilated areas.

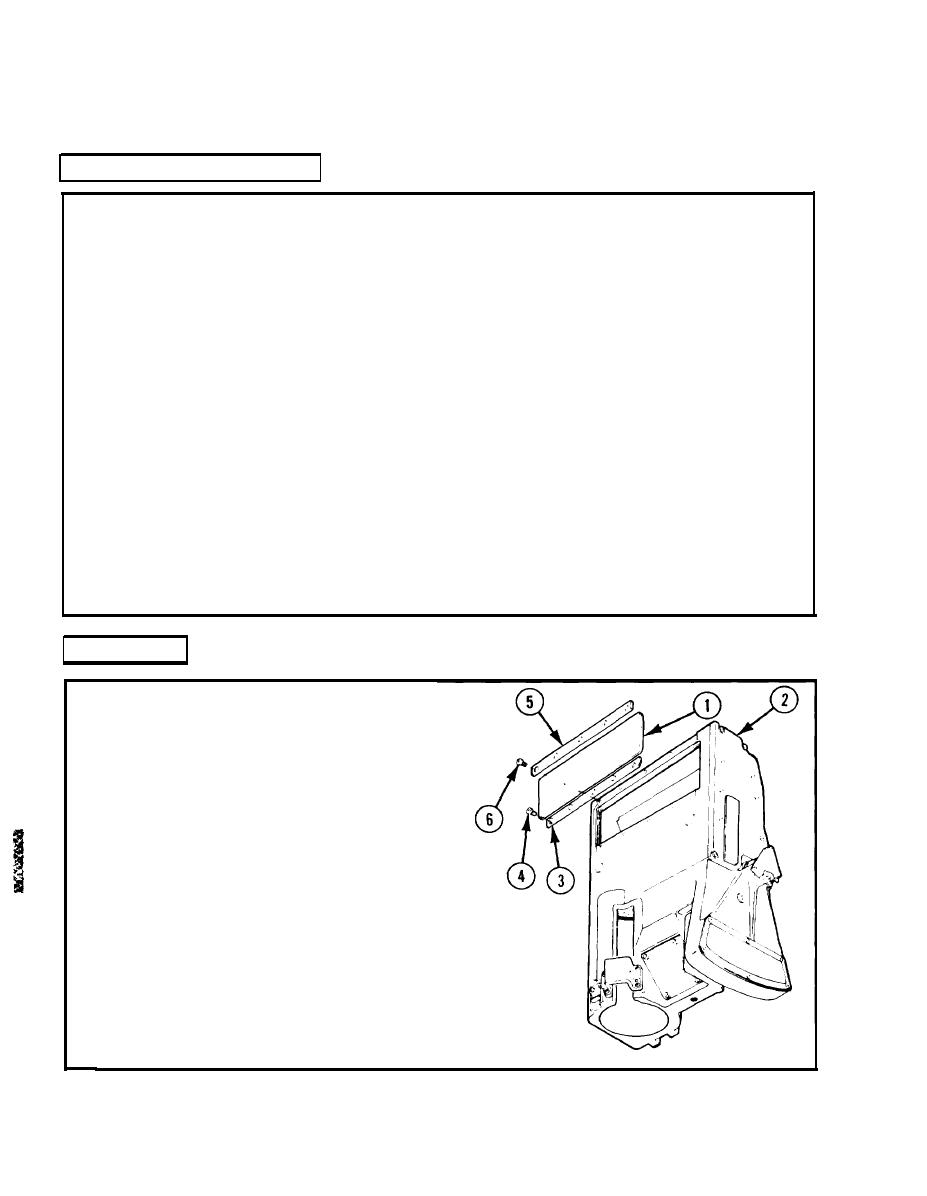

REASSEMBLY

Position new optical instrument window

1

(1) in housing of head assembly (2) and

apply sealing compound in beveled

recess around edge of optical instrument

window.

Secure optical instrument window (1)

2

with strip (3) at bottom using five

machine screws (4) and strip (5) at top

using five machine screws (6).

After optical instrument window has

3

been installed in head assembly, purge

and charge in accordance with TM

750-116.