TM 9-1240-401-34&P

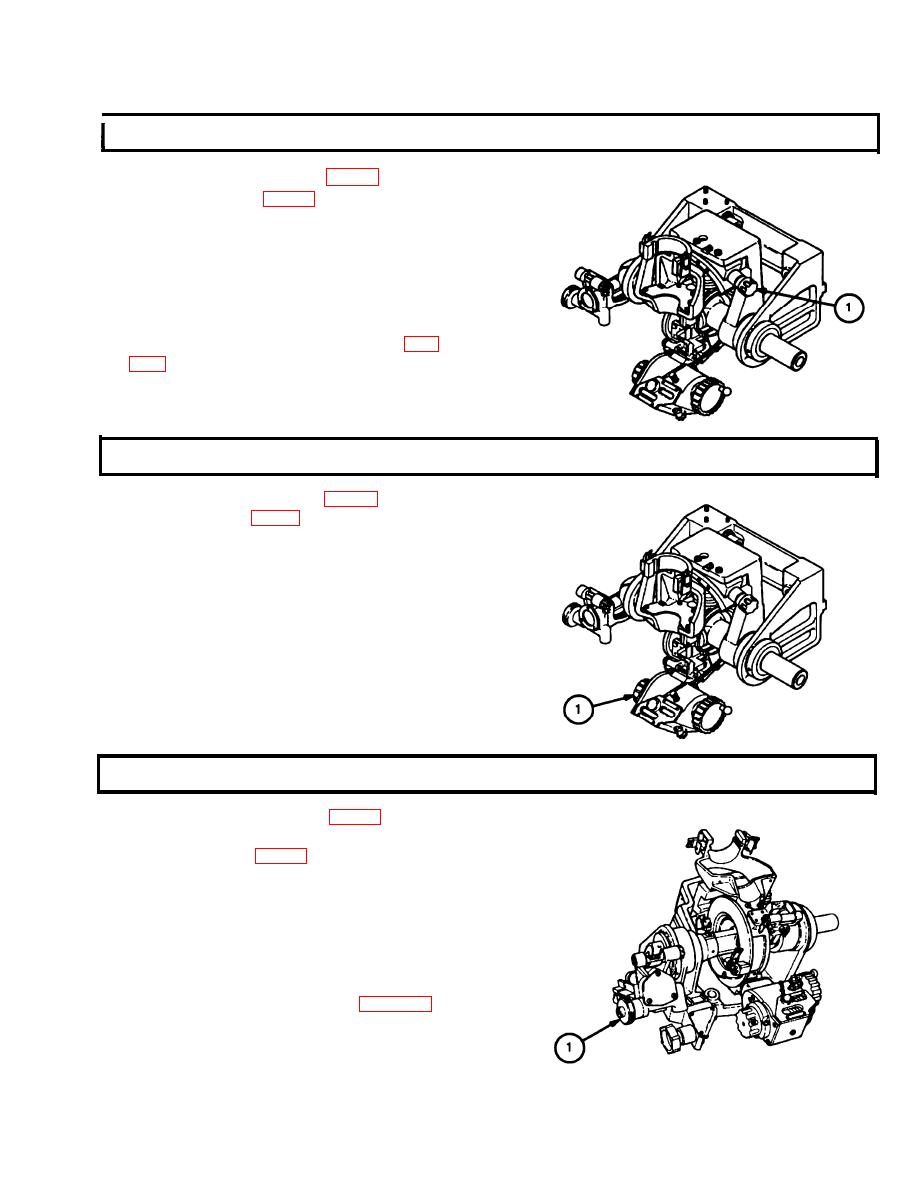

j. CHECKING CROSS-LEVEL MECHANISM KNOB RUNNING TORQUE

1 With torque wrench (Item 36, appx F) and adapter

(8599917) (Item 6, appx F), rotate cross-level

mechanism knob (1) one turn clockwise and one

turn counteclockwise

2 Measure the torque required to turn cross-level

mechanism knob (1). The torque must be between

3 and 6 pound-inches (0.33 and 0.67 N-m). If not,

repair according to repair procedure (ref. para

k. CHECKING ELEVATION CORRECTION KNOB RUNNING TORQUE

1 With torque wrench (Item 36, appx F) and adapter

(8599910) (Item 3, appx F), rotate elevation correc-

tion knob (1) one turn clockwise and one turn coun-

terclockwise.

2 Measure the torque required to turn elevation cor-

rection knob (1). The torque must be between 2

and 4 pound-inches (0.23 and 0.45 N-m). If not,

notify depot maintenance.

l. CHECKING QUADRANT LEVEL KNOB RUNNING TORQUE

1

With torque wrench (Item 35, appx F) and adapter

(8599910 for M145A1) (Item3, appxF) (8599911

for M145) (Item 4, appx F), rotate quadrant level

knob (1) one turn clockwise and one turn counter-

clockwise.

2

Measure the torque required to turn quadrant level

knob (1). The torque must be between 4 and 10

ounce-inches (0.028 and 0.071 N-m). If not, repair

according to repair procedure (ref. para 4-13).

4-59